PORCELAIN SLABS VACUUM LIFTER

RIGHETTI P12A-350

RIGHETTI P12A350/2-2500/750 pneumatic porcelain slabs vacuum lifter. Max load 350 kg with 12x 200 mm pads. Pneumatic 90° tilt. Adjustable position of suction pads and of cross arms. Other versions available

Porcelain slabs vacuum lifter RIGHETTI P12A-350 for sale online:

| Price | Discount | Net Price |

|---|---|---|

| 5,460 EUR | -12% | 4,805 EUR |

taxes excluded, prices subject to change without notice. Last update: 23rd Dec 2025

buy now

download

benefits PORCELAIN SLABS VACUUM LIFTER RIGHETTI

- Eliminates the need for unsafe and time-consuming lifting mechanisms such as hooks, slings or chains

- Less downtime between lifts

- Can lift material without displacing adjacent pieces

- Creates a powerful positive engagement of the load (hooks, slings and chains can shift or come loose, endangering employees)

- Reduces or eliminates need to use ropes to orient safetly the load

- Vacuum lifting systems are able to go where people should not be

- Audio alarms indicate unsafe lifting environments

how works PORCELAIN SLABS VACUUM LIFTER

A vacuum glass lifter is a lifting device, which, thanks to the vacuum created by a vacuum generator, permits fast and easy attachment, lifting and handling of sheets of glass. The vacuum is created by a vacuum generator supplied with electric pump ( AC, DC or battery powered ) or compressed air ( Venturi system).

Vacuum pump maintains a constant vacuum in the de-pressure reservoir, when activated, the system pulls a vacuum between the pad and object to be lifted, using a vacuum tank, previously loaded with the pump. Therefore the suction is immediate.

The structure of vacuum lifters may be fixed, tilting 0°-90° or rotating 360°. In relation to the weigth of the material to be lift, the vacuum lifters are comprised of two, four, six or more vacuum pads. Many models are available with extension or adjustable arms that offer a variety of pad configurations to accommodate difefrent load dimensions.

Suction Cups

The vacuum system was designed to ensure minimum vacuum dispersion, even if there is a power failure. The new suction cups so that they guarantee minimum vacuum dispersion and increased safety. During lab tests including simulation of a power failure, the cup was able to hold the load for up to 48 hours, going far beyond the limit set by the EN 13155:2009 standard. Suction cups come complete with a safety ring, and some also come with a double lip ring. Most lifters are provided with cups with a double spring system in order to best compensate the flexion of glass sheets and so that the cups sit better on the same sheets.

Control Unit

An on-board computer to manage the lifter as safely as possible. Verifies the operation of the lifter's main components and carries out self-diagnostics if a breakdown occurs. The control unit comes complete with microprocessors to control the power circuits. It monitors the level of vacuum in the system, reporting any anomalies with a visual and acoustic alarm. Manages and monitors batteries and a built-in economizer considerably lengthens battery life.

main controls PORCELAIN SLABS VACUUM LIFTER RIGHETTI P12A-350

The control system varies depending on the models, in the case of models with manual movements, the controls for suction and release are present on the frame or can be controlled by radio, in models equipped with electric movements, the radio control controls each function. The on-board computer allows the machine to be switched on and off, monitors the status of the battery, provides information on the operation and any alarms, and integrates the function of economizing energy consumption

- suction/release button

- rotation control

- board computer

- tilting control

- release

- suction

- tilting up

- suction

- rotation counterclockwise

- tilting down

- rotation clockwise

product reference PORCELAIN SLABS VACUUM LIFTER RIGHETTI P12A-350

- category: PORCELAIN SLABS VACUUM LIFTER

- brand: RIGHETTI

- model: P12A-350

- country of origin: ITALY

- SKU code: RIGPRSTN1201

- HS/HTS code (Harmonized Tariff Schedule): HS84289090(*)

- NCM code: 8427.10 (19) (*)

- availability: OnlineOnly

- item condition: NewCondition

(*) HS/HTS/NCM codes may be incorrect, please request a verification before to place the order.

compliance to normative PORCELAIN-SLABS-VACUUM-LIFTER RIGHETTI

The observance of the EN 13155 Standard and other directives is essential to satisfying safety requirements. RIGHETTI has developed and designed avant-garde components to improve and perfect safety systems. A latest generation control unit, custom developed and designed suction cups, a vacuum system made to guarantee the best hold—these are just a few of the results achieved by our team of designers. The Righetti Vacuum Lifter are fully compliant with all the relevant norms for lifting equipments, included EN13155, and are manufactured according to the indications provided by UNI EN ISO 9001.

e.u. guarantee

E.U. legislation provides a Free of charge, 2 years guarantee for private person, and 1 year for company (legal guarantee) on faulty goods, for all products we sell, this is important because it is a guarantee that the goods sold by us are covered by European protection. All goods we sell are invoiced by Silcom North UAB, a company registered in Vilnius, Lithuania. Every product we send is checked before departure, but in case there are any problems, the customer is required to notify us as soon as possible, and must not use the product until our withdrawal. In case the customer needs a repair, we are always available to assist him, even after the warranty expires.

why choose us

Because for 50 years we have been dealing with industrial supplies, we have seen technology evolve and needs change. Because we are used to working with customers from all over the world, because we believe that after-sales service is as important as the technical preparation of our staff. We like to listen to requests, and propose the best solutions.

videos PORCELAIN SLABS VACUUM LIFTER RIGHETTI P12A-350

Presentation video of the righetti p12a-350 pneumatic porcelain slabs vacuum lifter

features PORCELAIN SLABS VACUUM LIFTER RIGHETTI P12A-350

Filter

vacuum filter to protect against impurities

Single vacuum circuit

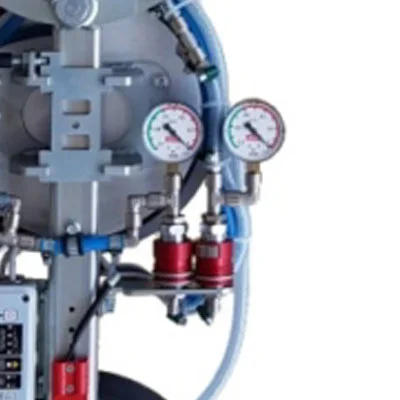

single vacuum circuits, with vacuum reserve and non return valve

Board computer

on board computer with battery level indicator, acoustic low vacuum warning, battery economizer

Repositionable pads

pads can be positioned in different configurations on the frame

Vacuum gauge

separate vacuum gauge for each vacuum circuit

Pneumatic tilt

90° pneumatic tilt

wrong translation? suggest correction