MOBILE COLUMNS LIFTS TRUCK

EUROGAMMA EGSXL50FS

EUROGAMMA EGSXL50FS electro-mechanical mobile column lifts. Set of 4 columns. Max load 5000 kg per column. Individually controllable or synchronized movements.

ask for information

download

benefits MOBILE COLUMNS LIFTS TRUCK EUROGAMMA

- The jacks can be controlled in sets of 4, 8, 12 etc. to perform single or multi vehicle synchronised lifts

- The modular control system allows the operator to configure the jacks to suit the required operation

- For multi vehicle simultaneous lifts, the control can be either by means of a central control panel or a number of linked mobile controllers

- Proven reliability and long life are provided by the use of an irreversible trapezoidal screw / lifting nut arrangement and a highly robust jack structure

- The enclosed design of the jack column means that moving parts are guarded, minimising the potential for an acm3ident in operation

- Twin microprocessor controls with watchdog systems ensure the safe operation of the jacks. Safety features such as phase correction / detection and load nut wear detection also maximise operational safety

how works MOBILE COLUMNS LIFTS TRUCK

Jack height is monitored by special twin channel absolute encoder, ensuring accurate synchronization and no loss of synchronization due to power failure. Additionally, this eliminates the need for limit switches and a pulse counter, so improving the reliability of the equipment. Twin microprocessor controls with watchdog systems ensure the safe operation of the jacks. Safety features such as phase correction/detection and load nut wear detection also maximize operational safety.

Control units

All lifting jacks are equipped with a control pendant that allows moving the jack locally. The pendant is used to make the "approach" phase (contact between jack and vehicle). Once the "approach" phase is completed, the lifting system, all jacks, can be moved synchronously from the main control unit or using the selected control pendant.

Mobile columns

Jack configuration can be customized to suit the customer’s application – lifting height, extending anvil, rail mounted, load cells for vehicle weighing etc. Max load from 5 tons up to 50 tons per jack.

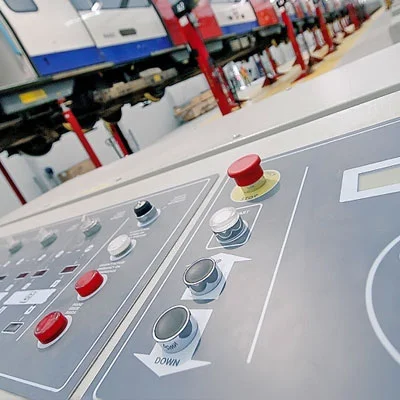

main controls MOBILE COLUMNS LIFTS TRUCK EUROGAMMA EGSXL50FS

Multiple solutions are available for the control of the jacks. Each jack is equipped with an independent pendant control system, which can be joined by a dedicated workstation, which controls the entire system

- 5 characters display

- Function button

- Key selector

- Signaling led mode and contact

- APP/SYNC selector

- UP button

- DOWN button

- Emergency button

product reference MOBILE COLUMNS LIFTS TRUCK EUROGAMMA EGSXL50FS

- category: MOBILE COLUMNS LIFTS TRUCK

- brand: EUROGAMMA

- model: EGSXL50FS

- country of origin: ITALY

- SKU code: EUGPRBUS1000

- HS/HTS code (Harmonized Tariff Schedule): HS84254900(*)

- NCM code: (*)

- availability: OnlineOnly

- item condition: NewCondition

(*) HS/HTS/NCM codes may be incorrect, please request a verification before to place the order.

compliance to normative MOBILE-COLUMNS-LIFTS-TRUCK EUROGAMMA

The jacks are fully compliant with all the relevant norms for vehicle lifting jacks and are manufactured under UNI EN ISO 9001 approved quality system, as well as being EC certified by an independent third pary, acredited by European Union

The design of Eurogamma lifting systems is always in compliance with the latest standards Compliance to: UNI EN 12100, UNI EN ISO 13857, EN 349, UNI EN ISO 13850, EN 1493, UNI EN ISO 9000, UNI EN ISO 9001, EN 60204-1, EN 60204-32, EN 61000-6-2, EN 61000-6-4, EN 13849-1

e.u. guarantee

E.U. legislation provides a Free of charge, 2 years guarantee for private person, and 1 year for company (legal guarantee) on faulty goods, for all products we sell, this is important because it is a guarantee that the goods sold by us are covered by European protection. All goods we sell are invoiced by Silcom North UAB, a company registered in Vilnius, Lithuania. Every product we send is checked before departure, but in case there are any problems, the customer is required to notify us as soon as possible, and must not use the product until our withdrawal. In case the customer needs a repair, we are always available to assist him, even after the warranty expires.

why choose us

Because for 50 years we have been dealing with industrial supplies, we have seen technology evolve and needs change. Because we are used to working with customers from all over the world, because we believe that after-sales service is as important as the technical preparation of our staff. We like to listen to requests, and propose the best solutions.

videos MOBILE COLUMNS LIFTS TRUCK EUROGAMMA EGSXL50FS

Presentation video of eurogamma mobile columns, for trucks and buses

features MOBILE COLUMNS LIFTS TRUCK EUROGAMMA EGSXL50FS

Jack height

jack height is monitored by special twin channel absolute encoder

Easy moving

each column can be moved independently and easily with his rubber or rail profile wheels, with manual or motorized movement.

Individual control

each jack is equipped with a control system that allows executing the contact phase of the vehicle to be lifted. also, permits to control the entire set of lifting jacks

Control bench

control bench, able to manage from 4 to 48 jacks.

Lifting screw

kinematic mechanism with single lifting screw of the irreversible trapezoidal type obtained by rolling of two nuts

Synchronised lifts

the jacks can be controlled in sets of 4, 8, 12 etc. to perform single or multi vehicle synchronised lifts.

wrong translation? suggest correction